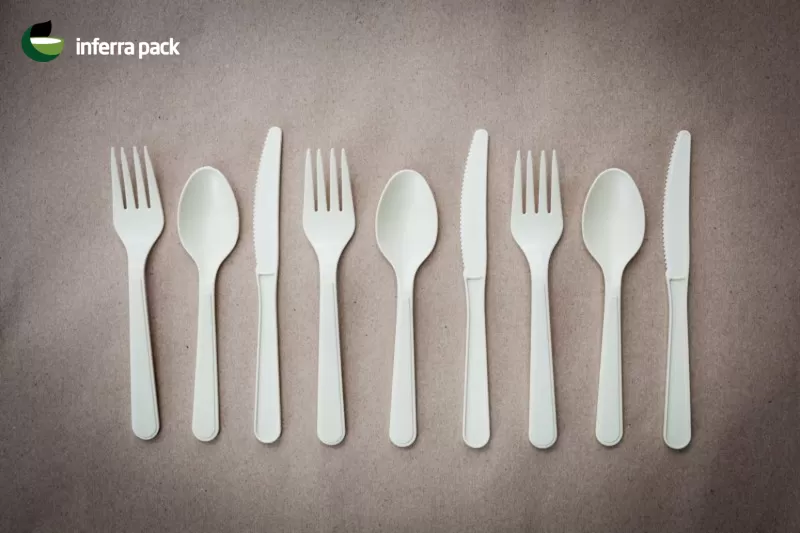

Compostable Take Away packaging and disposable CPLA cutlery

May 2021

Is PLA disposable food packaging a sustainable alternative to plastic?

Plastic pollution is beyond doubt one of the major threats currently posed to the environment. Uncontrolled consumption of disposable products has led to massive amounts of plastic waste ending up in our soil, water, air, and even human body. According to WebMD report, microplastics are found in all major human organs in autopsies (1). Similarly, some experts predict that plastics could outweigh fish in the world oceans by the year 2050 (2).This is certainly worrying, and a lot of governments and international organisations are beginning to develop strategies for a sustainable future. There are four courses of actions to help us in this never-ending battle with plastic waste. Reducing, reusing, recycling and replacing – these are the main pathways to cutting down the plastic waste.The 4Rs rules in foodservice packaging

To reduce waste means to purchase only what you need and choose products with less packaging. By reusing we mean repurposing items and giving them new life, for instance, you can donate unwanted goods to thrift stores and buy from these places as well. Recycling involves separating your rubbish and making sure it’s discarded properly. To replace means to find alternative materials that can substitute plastic. Bio-based plastic is believed to be a possible solution to plastic waste problem.Sustainable foodservice packaging: what is PLA?

PLA (or polylactic acid) is a specific type of thermoplastic, which is made from plants, such as sugarcane or cornstarch. PLA was first invented in 1920 by Wallace Carothers, while he was trying to create an eco-friendly plastic for chemical manufacturer DuPont. The production of such plastic turned out to be rather costly, so it was put on pause. Decades later, Patrick Gruber and his wife Sally succeeded at producing PLA from corn with a household stove. This markedly reduced the cost of PLA production. The process of PLA production is as follows: first, corn kernels are soaked in a mixture of hot water and sulfur dioxide, which breaks them down into fiber, protein and starch. Later, corn oil is separated from the starch and the kernels are ground. After that, a long-chain polymer is formed with the help of citric acids. This polymer is used as a main component of plant-based plastic. Currently, PLA is the cheapest bioplastic to make and it’s widely used in production of disposable food packaging, plastic films, bottles and biodegradable medical devices. CPLA (crystallised polylactic acid) is a type of PLA with superior heat resistance. It is used to produce single-use disposable cutlery. It can endure temperatures up to +90˚C, meanwhile regular PLA can’t be heated over +40˚C.

What are the benefits of PLA disposable food packaging?

The biggest advantage of using PLA disposable packaging is that it can be composted. It can completely degrade into water and carbon dioxide within 3 months in an industrial composting facility. Temperatures of at least +55-70˚C and specific degree of humidity are required for PLA to biodegrade. Since industrial composting facilities are not widely available in all cities and countries, we encourage you to separate PLA from other plastics in your recycling.Still, manufacturing plant-based plastic produces less CO2 and other greenhouse gases, thus decreasing the carbon footprint. In a 2017 study (3), experts predicted that moving to bio-based plastic from petroleum-based plastic would curb US greenhouse gas emissions by 25%. Using PLA allows us to lower the demand for petroleum-based plastics. What’s more, the amount of carbon dioxide emitted during combustion of PLA is prominently lower, than in petroleum-based plastics, such as Polystyrene, PET, Polypropylene and Polyethylene (4).

Features of PLA plastic cups and food containers:

- They are crystal clear for greater product visibility;

- The lids are leak-resistant and easy to put on and remove;

- Smooth rims make drinking a comfortable experience;

- Safe material, which contains no toxic components, such as BPA or PFAS.

We offer a range of packaging products for foodservice industry and disposable cutlery made from PLA and CPLA bioplastic. Shop our sustainable assortment of disposable cups, compostable food containers for Take away, clear salad bowls To Go, clear Deli containers, portion cups and lids for it, hot and cold drink paper cups with PLA coating, biodegradable Takeaway paper boxes with PLA coating, single-use cutlery.

(1) https://www.webmd.com/a-to-z-guides/news/20200817/autopsies-show-microplastics-in-all-major-human-organs#:~:text=17%2C%202020%20(HealthDay%20News),kidneys%20of%20donated%20human%20cadavers

(2) https://edition.cnn.com/2016/12/12/world/sutter-vanishing-help/

(3) https://iopscience.iop.org/article/10.1088/1748-9326/aa60a7

(4) https://www.unitika.co.jp/terramac/e/how/